How a DML Dal Maso jewel is born

Research, innovation and the ability to customise are the hallmarks of DML Dal Maso's working methods.

In a continuous fusion of craftsmanship and technical-industrial skills, the company works alongside the customer to satisfy every request.

From design to development, from production to finishing, DML Dal Maso creates custom-made jewellery for brands and companies that desire style, elegance and refinement.

3

01

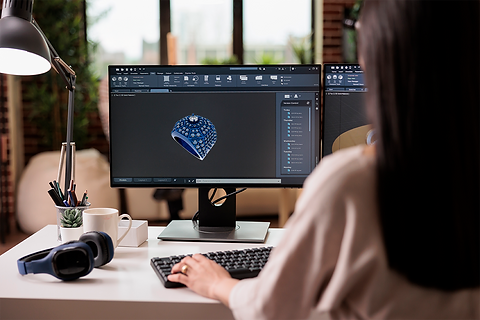

Design & planning:

from drawing to 3D prototype

The idea that becomes reality, the sketch that becomes 3D.

DML Dal Maso realises the models, conceived by the customer, with 3D systems that allow the future jewel to be immediately in hand

Design: from aesthetics to feasibility

Creativity, inspiration and innovation drive DML Dal Maso designers to design new ideas, ensuring attention to detail and meticulous attention to detail. Technical expertise and experience mean that the feasibility, durability and aesthetics of a sketch are immediately in view.

Co-creation and creative development

Having an idea, but not knowing how to model it is not a limitation with DML Dal Maso: the Creazzo-based goldsmith's designers create jewellery from any customer's guideline, be it an idea, a draft design, a photograph or an STL file.

3D Design in Jewellery

After the project is approved, the idea is further developed with innovative CAD software for 3D modelling. DML Dal Maso in this phase proposes to the customer the best production solutions for the jewel, respecting the original artistic indications but optimising them for the production.

Rendering: the precious in reality

The complete history for each object, including data sheet with photos, and a reference master make up the render that is developed in DML Dal Maso with 3D design systems.

Wax prototyping

The digital project becomes physical with high-resolution wax or resin prototyping. The tangible sample makes it possible to see the details as minutely as if the jewel had already been created.

Manual modelling:

the craftsmanship of the artisan

Technology has not totally replaced manual skill: some jewellery still requires craftsmanship. The goldsmith masters of DML Dal Maso take over in the most difficult and particular cases to model the jewel by hand: the artists are able to take over the technological difficulty but also to create the prototype from the beginning.

Industrialisation optimised for each jewel

Optimising to improve: DML Dal Maso analyses all the phases of the production process to find the best solution for each project. Paying attention to volumes and thicknesses, the Creazzo-based goldsmith plans the technologies to be used and the processing methods for each jewel or line.

.

02

Technology at the service of the goldsmith tradition in DML Dal Maso

The technological innovation of DML Dal Maso increases production capacity and expands skills in a continuous virtuous cycle that satisfies the customer. The company thus responds to all requests for third-party production: from the creation of unique pieces to mass production for companies, brands and jewellers.

Quick prototyping

Reverse Engineering (Reverse Engineering), the scanner and the 3D printer make it possible to create any piece of jewellery from just a drawing, a sketch, an idea or a previous model, without digital history.

The wax model, produced with the 3D printer, with lost wax casting becomes a prototype for a unique creation or a new line.

Microcasting: ancient techniques for modern production

After the creation of the 3D design or metal model, we move on to the creation of the wax prototype or directly to mass production using rubbers.

The rubber becomes a resistant matrix that maintains the shape of the jewel, allowing the faithful reproduction of the model. The resulting wax specimens are then assembled to form the casting cluster, ready for the next stages of manufacture.

Protofusion from 3D printing

DML Dal Maso produces using both micro-casting and pro-casting. While micro-casting is based on a negative mould, made of rubber, the injection of hot wax and casting with the desired metal, pro-casting is the evolution. The innovative process doesn't use rubber and exploits 3D printing technology to create the model.

Mechanical work to create jewellery

Customer needs always come first at DML Dal Maso. When it is necessary to optimise machining times and costs, mechanics is put at the service of jewellery: lathes and milling cutters make it possible to speed up the production of jewellery with complex details. Laser cutting, on the other hand, guarantees maximum precision for engraving, diamond cutting and special shapes, enhancing each creation with impeccable workmanship.

.

03

DML Dal Maso's craftsmanship for jewellery made in Italy

The goldsmith masters, custodians of ancient manufacturing techniques, are the beating heart of DML Dal Maso.

With their profound knowledge and skill they create each piece of jewellery and continue the renowned Vicenza craftsmanship tradition.

The skilful hands of the goldsmith at the bench

The assembling, sanding, flame soldering, finishing and repairing of DML Dal Maso are craftsmanship: the goldsmiths at the bench employ their skilled hands in these processes every day.

Preserving and preserving the know-how of the craftsmen of the Vicenza goldsmith district è part of DML Dal Maso's mission.

Laser welding machine for manual processing

In DML Dal Maso's workshop, craftsmanship is continually combined with technology: laser welding, used both for the creation of jewellery and for its assembly and repair, guarantees the highest quality of the final product.

Setting and setting: how to make stones shine

While setting highlights the stone, leaving it in the limelight, setting emphasises the marriage of stone and metal.

DML Dal Maso's diamonds, precious, semi-precious and hard stones can be jaw-set (square, triangular, round, rectangular, with grains and beads or pavé) or set, rabbet or prong-set, with a rough cut, swallow-net or whisker cut.

Master craftsmen carry out both setting and embedding also in the wax model to ensure quality control and feasibility from the design stage.

04

Personalisation down to the smallest detail: the finish

The idea is concrete, but there is still something missing: from cleaning to electroplating, DML Dal Maso concludes the production process and fulfils every finishing requirement for customised jewellery for every customer.

Polishing for fine finishes

Polishing delicacy is essential to preserve the designed shape. The craftsmanship and continuously trained knowledge of the DML Dal Maso goldsmiths enables the process to be optimised.

Incisione laser

Characters, sizes, blackening, logos and symbols are just some of the laser engravings that DML Dal Maso produces. The wide range of applications and effects is performed with a laser marker.

.Galvanic

The company finishes its jewellery with various galvanic processes: from palladium plating to rhodium plating, from oxidation to gilding and cataphoresis, DML Dal Maso performs the required work on various metals to complete each creation according to the customer's needs.

Enamel & Paint

The enamel and varnish jewellery is made in the DML Dal Maso workshop by skilled craftsmen. The various colours are enamelled or varnished according to the type of material and customer request.

.05

Quality control and safe shipping: additional services

The perfect dress for a jewel è packaging: DML Dal Maso thinks not only about the package, but also about safety.

The product thus becomes even more precious.

Quality control

A specific department for quality control and an office dedicated to customers who want to carry out the analysis themselves: DML Dal Maso not only controls every single step, but also devotes much attention to the final quality to guarantee the required standards and more.

Customised packaging and logistics

Once finished, DML Dal Maso jewellery is not abandoned: a special department takes care of the wrapping, packaging and logistics so that customers have the perfect piece of jewellery.

The service è customised to the needs of the customers, who can also choose the packaging.

.